The VINES automobile manufacturing plant is one of Vietnam’s key industrial manufacturing projects, aiming to establish a modern, highly automated, and internationally compliant car assembly line. Stringent requirements on space, precision, production environment, and continuous operation make the design and installation of the factory a major challenge.

Hung Thinh was entrusted with the installation of the entire precast steel structure and auxiliary systems for the VINES plant, directly contributing to the project’s success.

Strict Technical Requirements

- Large-span structure without intermediate columns to ensure operational space for the automated production line.

- Industrial doors, high-speed sliding doors, and rolling shutters to support logistics and assembly activities.

- Ventilation, lighting, and dust control environment meeting standards for electrical-mechanical component manufacturing plants.

- Compliance with ISO standards for industrial factory design in the automotive sector.

Construction Solutions from Hung Thinh

-

Precast steel structures designed and fabricated by Hung Thinh at the factory, ensuring high precision in welds and connection holes.

-

On-site assembly organized in optimized phases, combining safe crane lifting with modern equipment.

-

Integrated auxiliary systems including industrial doors, forced ventilation, energy-saving LED lighting, and industrial drainage.

-

Strict control of progress, quality, and safety, coordinated directly with the main contractor and international supervision consultants.

Results & Value Delivered

-

Completed on schedule, enabling the investor to commission the plant as planned.

-

Construction quality meets international standards, fulfilling rigorous inspection requirements from foreign partners.

-

Contributed to creating a modern, integrated, and sustainable automobile production facility with regional influence.

Huưng Thinh – A Trusted Partner in Heavy Industrial Construction

With extensive experience in industrial structures, Hưng Thịnh continues to prove its capability through demanding projects like the VINES automobile plant. A professional engineering team, modern equipment, and stringent control processes make Hung Thinh a trusted partner for many large domestic and international corporations.

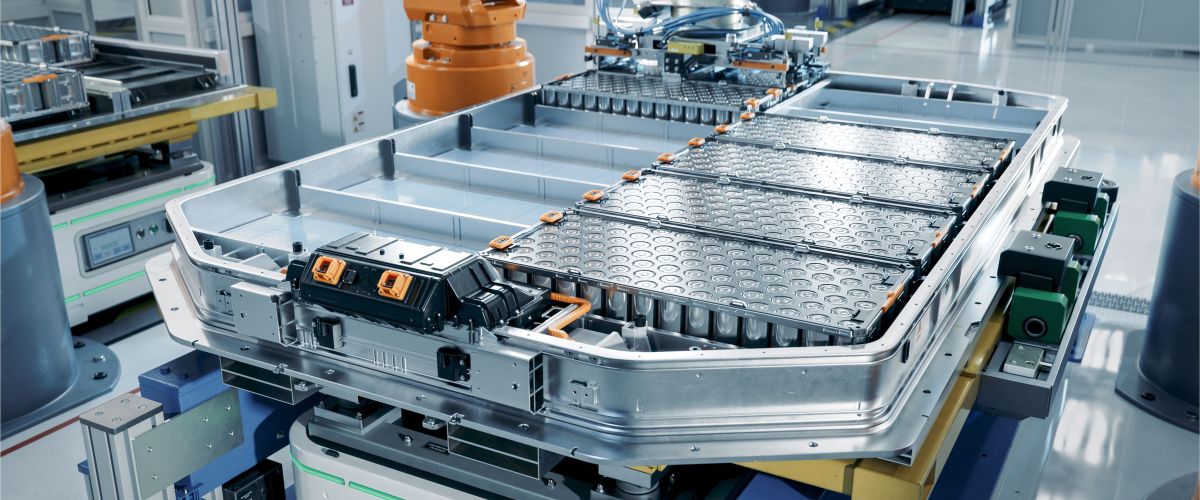

VG Battery Production Line Project

Amid rapid development in clean energy and battery technology, the VG battery production line project aims to build a modern factory that meets international standards in environment, productivity, and operational safety. To meet these stringent criteria, Hung Thinh was selected as the steel structure contractor, forming the foundation for the entire high-tech battery production line.

Special Requirements of the Battery Industry

-

Lithium battery and next-generation battery production require clean, airtight factory spaces minimizing dust and contaminants affecting cell quality.

-

Flexible structure to allow easy expansion or adjustment of the production line.

-

Compliance with safety and explosion prevention standards, especially in chemical and battery packaging areas.

-

Compatibility with high-tech equipment, robots, and automated production lines.

Hung Thinh’s Specialized Solutions

-

Installation of precast steel structure: Modular factory frames ensure high load-bearing capacity and flexible equipment layout.

-

Integration of technical floors and piping systems suitable for gas treatment, chemical handling, and automation equipment zones.

-

Coordinated construction with M&E contractors, cleanroom systems, and fire protection to ensure overall schedule.

-

Strict safety and quality control via construction monitoring and phased acceptance.

Project Benefits

-

Ensures delivery of production line on schedule to support investor’s commercial production plans.

-

Optimizes construction costs through rational structural design and synchronized execution.

-

Meets international environmental and safety standards, preparing the plant for ISO, RoHS, or UL certification.

Hung Thinh – A Solid Foundation for Clean Energy’s Future

The success of the VG battery production line project affirms Hung Thinh’s capacity in high-tech construction. Beyond steel structure contracting, Hung Thinh is a strategic partner for renewable energy, clean industry, and high-tech manufacturing corporations.